膜盒压力表和波纹管压力表的优缺点

膜盒压力表的优缺点:

优点:

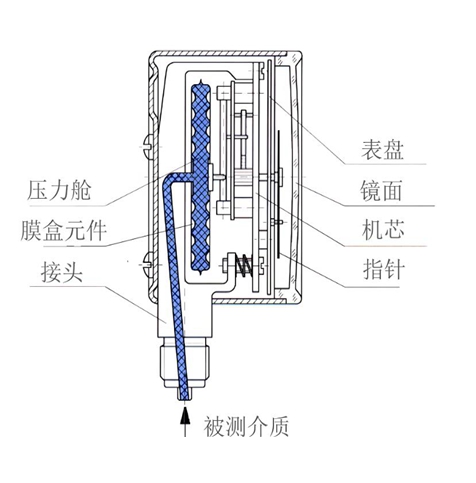

结构简单:内部结构相对不复杂,主要由膜盒、传动机构、指示部件和外壳等组成,没有过于复杂的机械结构,这使得其制造和维护成本相对较低,生产和维修都比较方便。

测量精度较高:对于微小压力的测量具有较好的精度,能够准确地反映出较小压力的变化,适用于对压力测量精度要求较高的场合,比如一些需要精确控制气体压力的实验环境、对压力变化敏感的工艺流程等。

稳定性好:膜盒的弹性形变相对较为稳定,在测量过程中受外界干扰因素的影响较小,能够保持较为稳定的测量结果,确保了测量数据的可靠性。

适用范围广:可用于测量对铜合金不起腐蚀作用、无爆炸危险的气体的微压和负压,广泛应用于锅炉通风、气体管道、燃烧装置等设备上。

指示明显:表盘上的指针指示清晰,读数方便,操作人员可以快速准确地读取压力数值。

缺点:

测量范围有限:通常膜盒压力表的测量范围在 - 80~60000Pa 之间,只能适用于测量微小压力和较低压力的场合,对于高压环境的测量则不适用。

对温度敏感:在温度变化较大的环境中,膜盒的弹性特性可能会受到一定的影响,从而导致测量误差的增大。因此,在高温或低温环境下使用时,需要对膜盒压力表进行温度补偿或采取其他防护措施。

波纹管压力表的优缺点:

优点:

输出推力大:波纹管在受到压力作用时会产生较大的位移,能够将压力信号转化为较大的推力,通过传动机构驱动指针转动,使得压力表的指示更加明显、准确。

适用于低、中压测量:在低、中压范围内具有较高的灵敏度和测量精度,能够准确地测量出较低压力和中等压力的变化,特别适用于一些对低压测量要求较高的场合,如城市燃气管道、通风系统等。

可测量腐蚀性介质:可以用来直接测量不会结晶且具有一定腐蚀性的气体或液体的压力,对于一些具有腐蚀性的工作介质具有较好的适应性。

缺点:

需要环境温度补偿:波纹管的材料特性受温度影响较大,温度变化会导致波纹管的弹性模量发生变化,从而影响压力表的测量精度,因此在使用过程中需要进行环境温度补偿。

不能用于高压测量:由于波纹管的结构强度有限,无法承受过高的压力,所以其测量范围受到限制,不适用于高压环境的压力测量。

线性度较差:压力位移线性度相对较差,迟滞误差较大,通常精度只能达到 1.5 级左右。为了提高其线性度,通常需要在波纹管内部安装螺旋弹簧等辅助装置。

Advantages and disadvantages of membrane box pressure gauge and bellows pressure gauge

Advantages and disadvantages of capsule pressure gauge:

advantage:

Simple structure: The internal structure is relatively simple, mainly composed of a membrane box, transmission mechanism, indicator components, and housing, without overly complex mechanical structures. This makes its manufacturing and maintenance costs relatively low, and production and maintenance are relatively convenient.

High measurement accuracy: It has good accuracy for measuring small pressures and can accurately reflect changes in small pressures. It is suitable for situations that require high pressure measurement accuracy, such as experimental environments that require precise control of gas pressure and process flows that are sensitive to pressure changes.

Good stability: The elastic deformation of the membrane box is relatively stable, and it is less affected by external interference factors during the measurement process, which can maintain relatively stable measurement results and ensure the reliability of the measurement data.

Wide applicability: It can be used to measure the micro pressure and negative pressure of gases that do not corrode copper alloys and pose no explosion hazard. It is widely used in equipment such as boiler ventilation, gas pipelines, and combustion devices.

Obvious indication: The pointers on the dial indicate clearly and are easy to read, allowing operators to quickly and accurately read pressure values.

Disadvantages:

Limited measurement range: Typically, the measurement range of a bellows pressure gauge is between -80~60000Pa, which can only be used for measuring small and low pressures, and is not suitable for measuring high-pressure environments.

Temperature sensitivity: In environments with large temperature changes, the elastic properties of the membrane box may be affected to some extent, leading to an increase in measurement errors. Therefore, when used in high or low temperature environments, temperature compensation or other protective measures need to be taken for the bellows pressure gauge.

Advantages and disadvantages of bellows pressure gauge:

advantage:

High output thrust: The bellows will produce a large displacement when subjected to pressure, which can convert the pressure signal into a large thrust. Through the transmission mechanism, the pointer is driven to rotate, making the indication of the pressure gauge more obvious and accurate.

Suitable for low and medium pressure measurement: It has high sensitivity and measurement accuracy in the low and medium pressure range, and can accurately measure changes in low and medium pressures. It is particularly suitable for situations that require high low pressure measurement, such as urban gas pipelines, ventilation systems, etc.

Measurable corrosive media: can be used to directly measure the pressure of gases or liquids that do not crystallize and have a certain degree of corrosiveness, and has good adaptability to some corrosive working media.

Disadvantages:

Environmental temperature compensation is required: The material properties of the bellows are greatly affected by temperature, and temperature changes can cause changes in the elastic modulus of the bellows, thereby affecting the measurement accuracy of the pressure gauge. Therefore, environmental temperature compensation is required during use.

Cannot be used for high-pressure measurement: Due to the limited structural strength of the bellows, it cannot withstand excessive pressure, so its measurement range is limited and not suitable for pressure measurement in high-pressure environments.

Poor linearity: The linearity of pressure displacement is relatively poor, with a large hysteresis error, and usually the accuracy can only reach about 1.5 levels. To improve its linearity, it is usually necessary to install auxiliary devices such as coil springs inside the corrugated tube.