流量开关和流量计的应用

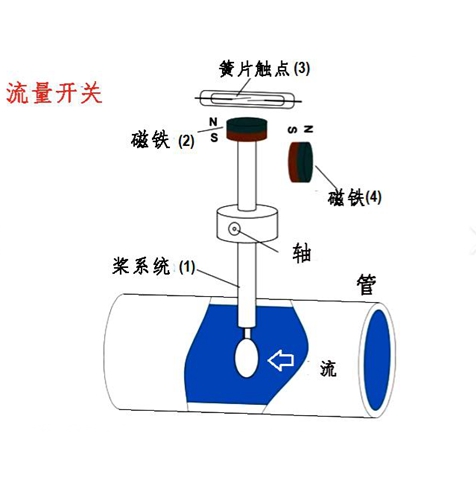

流量开关:

工业生产:在各类工业制造过程中,流量开关可用于监测管道内液体(如化工原料、润滑油等)或气体(如压缩空气、工业气体等)的流动情况。当流量低于或高于设定值时,触发开关动作,实现设备的启停控制或报警,保障生产过程的安全和稳定。例如,在自动化生产线中,确保物料的稳定供应;在一些关键设备的冷却系统中,防止冷却液断流。

HVAC 系统(供暖、通风与空调系统):用于监测空调系统中冷冻水、冷却水等流体的流量,确保系统正常运行。当水流量不足时,流量开关可及时发出信号,避免空调机组因缺水而损坏。

给排水系统:在城市供水管道、建筑给排水管道中,流量开关可用于检测水流状态,实现对水泵的自动控制。例如,当市政供水管网来水流量不足时,控制水泵停止工作,防止水泵空转损坏;在排水系统中,可监测污水排放流量,异常时及时报警。

能源管理:在能源输送管道(如天然气管道、燃油管道)中,流量开关可用于监测能源的输送流量,为能源的合理分配和使用提供数据支持,同时在流量异常时及时采取措施,避免能源浪费和安全事故。

流量计:

工业过程控制:广泛应用于各种工业生产流程中,精确测量不同介质(如液体、气体、蒸汽等)的流量,为生产工艺的优化、质量控制提供准确的数据依据。比如在石油化工行业,精确测量各种原料和产品的流量,以确保生产过程的准确性和稳定性;在制药行业,严格控制药液的流量,保证药品的质量和一致性。

能源计量:在电力、燃气、热力等能源供应领域,用于计量能源的消耗量。例如,在燃气公司,通过流量计准确计量用户的燃气使用量,进行计费和能源管理;在热电厂,对蒸汽的流量进行精确测量,以评估能源的产出和消耗情况,提高能源利用效率。

环境保护:在污水处理、废气排放监测等环保领域发挥重要作用。测量污水的流量,确保污水处理设施的正常运行和处理效果;监测废气排放的流量,帮助企业控制污染物的排放,达到环保标准要求。例如,在污水处理厂,根据流量计的数据来调整处理工艺和设备运行参数;在工厂的废气排放管道上,安装流量计实时监测废气排放情况。

交通运输:在航空航天领域,用于测量飞机燃油系统、发动机进气系统等的流量;在汽车制造中,用于发动机燃油喷射系统、冷却系统等的流量测量,优化发动机性能和燃油经济性。例如,精确控制燃油喷射量,提高发动机的燃烧效率,降低油耗和排放。

水利工程:用于河流、渠道、水库等的水流量监测,为水资源的合理调度、防洪抗旱决策提供数据支持。比如在水文站,通过流量计长期监测河流的流量变化,为水利部门提供水文数据;在大型水利枢纽工程中,根据流量数据来控制闸门的开启和关闭,实现水资源的科学调配。

Application of flow switches and flow meters

Flow switch:

Industrial production: In various industrial manufacturing processes, flow switches can be used to monitor the flow of liquids (such as chemical raw materials, lubricants, etc.) or gases (such as compressed air, industrial gases, etc.) in pipelines. When the flow rate is lower or higher than the set value, the switch action is triggered to achieve the start stop control or alarm of the equipment, ensuring the safety and stability of the production process. For example, in automated production lines, ensuring a stable supply of materials; In the cooling system of some key equipment, prevent the coolant from flowing out.

HVAC system (heating, ventilation, and air conditioning system): used to monitor the flow of fluids such as chilled water and cooling water in the air conditioning system, ensuring the normal operation of the system. When the water flow is insufficient, the flow switch can send a signal in a timely manner to avoid damage to the air conditioning unit due to water shortage.

Water supply and drainage system: In urban water supply pipelines and building water supply and drainage pipelines, flow switches can be used to detect water flow status and achieve automatic control of water pumps. For example, when the incoming water flow of the municipal water supply network is insufficient, the water pump should be controlled to stop working to prevent damage caused by idling of the water pump; In the drainage system, the sewage discharge flow can be monitored and an alarm can be triggered in a timely manner in case of abnormalities.

Energy management: In energy transmission pipelines (such as natural gas pipelines and fuel pipelines), flow switches can be used to monitor the flow rate of energy transmission, provide data support for the rational allocation and use of energy, and take timely measures in case of abnormal flow to avoid energy waste and safety accidents.

Flowmeter:

Industrial process control: widely used in various industrial production processes, accurately measuring the flow rate of different media (such as liquids, gases, steam, etc.), providing accurate data basis for the optimization of production processes and quality control. For example, in the petrochemical industry, precise measurement of the flow rate of various raw materials and products is necessary to ensure the accuracy and stability of the production process; In the pharmaceutical industry, strict control of the flow of drugs is necessary to ensure the quality and consistency of the drugs.

Energy metering: used in the field of energy supply such as electricity, gas, and heat to measure the consumption of energy. For example, in gas companies, users' gas usage is accurately measured through flow meters for billing and energy management; In thermal power plants, precise measurement of steam flow is carried out to evaluate energy output and consumption, and improve energy utilization efficiency.

Environmental protection: plays an important role in environmental protection fields such as sewage treatment and waste gas emission monitoring. Measure the flow rate of sewage to ensure the normal operation and treatment effectiveness of sewage treatment facilities; Monitor the flow rate of exhaust emissions to help companies control pollutant emissions and meet environmental standards. For example, in sewage treatment plants, the treatment process and equipment operating parameters are adjusted based on the data from flow meters; Install flow meters on the factory's exhaust emission pipelines to monitor real-time exhaust emissions.

Transportation: In the aerospace field, it is used to measure the flow rate of aircraft fuel systems, engine intake systems, etc; In automobile manufacturing, flow measurement is used for engine fuel injection systems, cooling systems, etc. to optimize engine performance and fuel economy. For example, precise control of fuel injection quantity can improve the combustion efficiency of the engine, reduce fuel consumption and emissions.

Water conservancy engineering: used for monitoring water flow in rivers, channels, reservoirs, etc., providing data support for the rational scheduling of water resources, flood control and drought resistance decisions. For example, at hydrological stations, long-term monitoring of river flow changes through flow meters provides hydrological data for water conservancy departments; In large-scale water conservancy hub projects, the opening and closing of gates are controlled based on flow data to achieve scientific allocation of water resources.